For thin walls where an insertion at the center of the wall would be sufficient to reach both walls a good rule of thumb would be to choose a vibrator with a radius of influence equal to 3 4 the total thickness of the wall.

Vibrated form finish concrete wall.

Sonotube finish free concrete forms are manufactured with the stripcord filament mounted inside the tube.

Finish f5 this finish is required for formed concrete surfaces where plaster stucco or wainscoting is to be applied.

Anyone who runs across this thread for info on vibrating motors tables and concrete mould casting the greatest leap i made when starting in this was studying frequency oscillation and weight force usually in kgf or knf things i discovered were more is definitely not better air bubbles tend to migrate toward the vibration concrete form vibrators will blow apart a plasic mould rechargable.

Steel lining or steel sheathing is not permitted.

Since a coarse textured surface is needed for bond the concrete should be cast against rough faced s1s2e form boards.

Download this easy help form for concrete walls and columns today.

When pulled with a hammer pry bar or other tool handle the stripcord strap cuts right through the form wall.

The stripcord stripping filament eliminates the time consuming process of cutting the form away.

Efco 16 high x 12 wide wall form efco s hi pro form 16 high and two 6 wide wall forms were equipped with 8 model svrws 4000 vibco pneumatic wedge type vibrators.

With surface vibration large vibrators sometimes called jumpers are directed manually onto the surface of the poured concrete.

The concrete mixture will use type ii cement with retarders and is estimated to weigh 2200 kg m3 sheathing will be 1 2 x 2 4 m sheets of 22 2 mm thick class iplyform with face grain perpendicular to studs.

A high capacity concrete pump filled the form in 5 minutes.

Form oil should not be used.

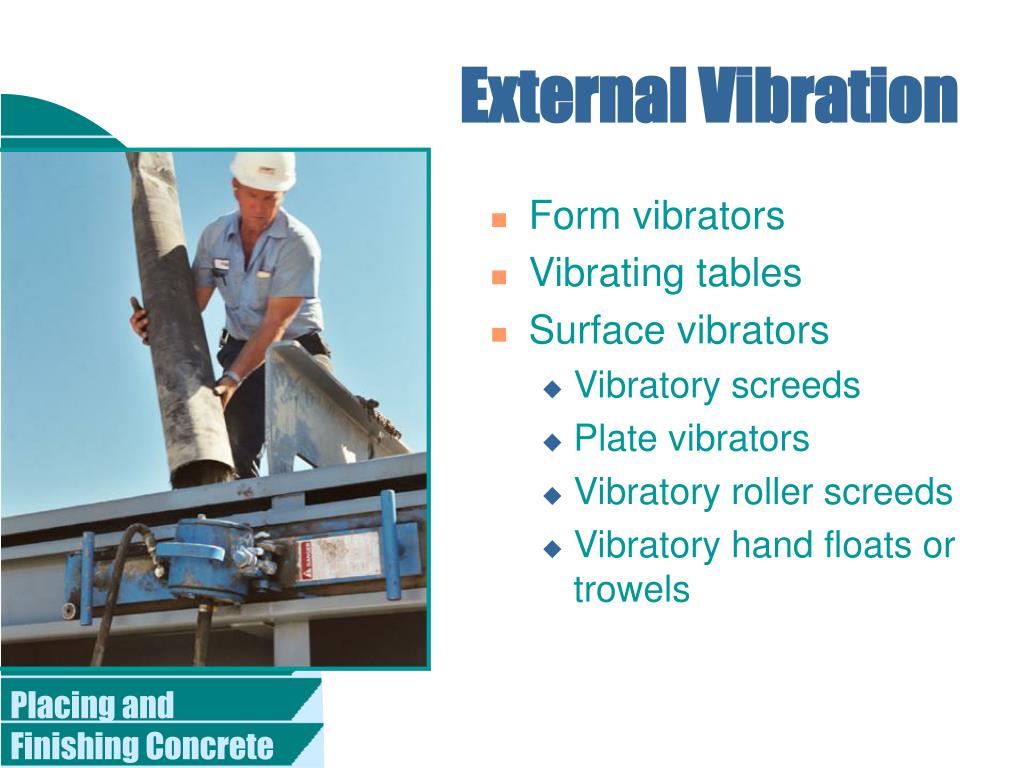

In concrete vibration external vibrators are electric or pneumatic concrete vibrators that mount to the exterior side of form work and cover a large area and usually you can space them 6 apart.

Forms are being designed for a 3 5 m high concrete wall to be poured at a rate of 1 8 m h internally vibrated at a temperature of 32 c.

The forms after the concrete sets.

Here are some tips for perfecting poured concrete with vibration.

A special bracket was designed by efco and vibco s engineers.

We re the concrete vibrator guys call us right now at 800 633 0032 if you need immediate delivery can t find the information you need or if you need help sizing and selecting the right vibrators for your forms.

When vibrating a wall the important consideration is to make sure that all of the concrete is exposed to the vibration.

Problems that commonly occur when using shoring equipment are mitigated by use of a concrete vibrator which consolidates concrete and refines the pouring process.

Formwork vibration is commonly used in precast concrete construction and involves mounting the vibrators to the outsides of the concrete forms for larger pours the external form vibrators are often spaced 6 feet apart.