For thin walls where an insertion at the center of the wall would be sufficient to reach both walls a good rule of thumb would be to choose a vibrator with a radius of influence equal to 3 4 the total thickness of the wall.

Vibrating concrete walls.

Problems that commonly occur when using shoring equipment are mitigated by use of a concrete vibrator which consolidates concrete and refines the pouring process.

Here are some tips for perfecting poured concrete with vibration.

Watch this video to see an example of how the area of influence of the vibration affects the concrete within the wall.

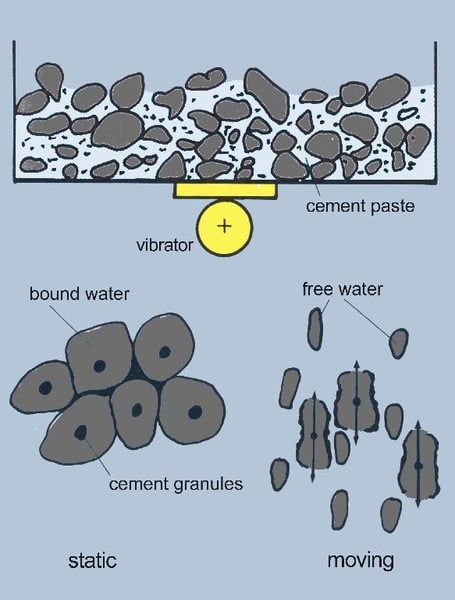

One of the most important steps when pouring concrete is the consolidation or vibration of concrete.

Honeycombing occurs when concrete has.

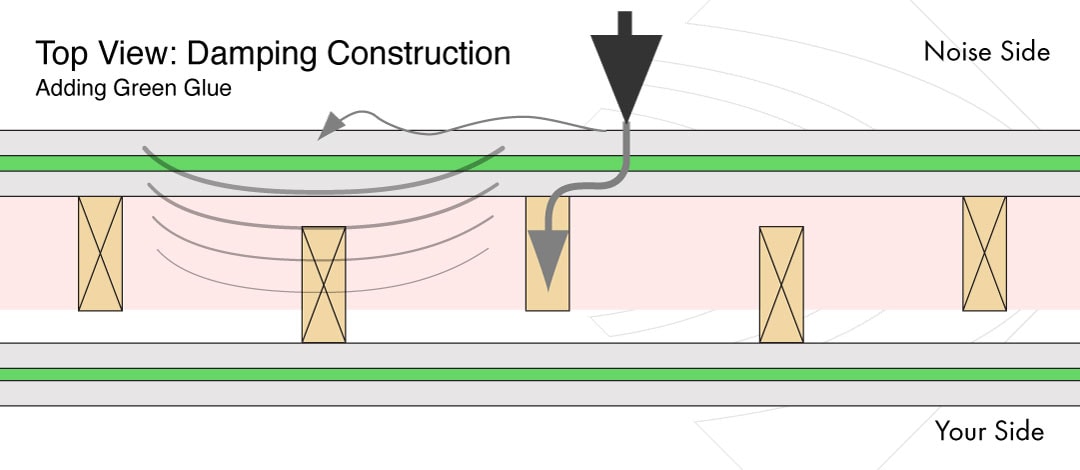

Formwork vibration is commonly used in precast concrete construction and involves mounting the vibrators to the outsides of the concrete forms for larger pours the external form vibrators are often spaced 6 feet apart.

Concrete vibrators if used properly will help consolidate concrete and will reduce the number of air pockets inside the concrete mass you can use internal vibrators or external vibrators depending on the application and where the concrete is being placed.

The use for external vibrators include floor to ceiling walls beam and one sided blind walls.

When vibrating a wall the important consideration is to make sure that all of the concrete is exposed to the vibration.

Only 3 left in stock order soon.

Area of influence for concrete vibrators.

The basic principles of placement and vibration are the same for any placing equipment used.

Reduce cold joints honeycombing and bugholes by training workers how to place and vibrate concrete in walls.

Vevor ac concrete vibrator 110v motor vibrating motor 100w single phase ac electric vibrating motor aluminum alloy case 3600rpm asynchronous vibration motor 2m cable concrete vibrator ip65 waterproof.

One such a problem is honeycombing.

In the construction industry there are many challenges regarding concrete quality.

In concrete vibration external vibrators are electric or pneumatic concrete vibrators that mount to the exterior side of form work and cover a large area and usually you can space them 6 apart.

Using external vibration on concrete formwork provides the smoothest possible finish and the best consolidation.

With surface vibration large vibrators sometimes called jumpers are directed manually onto the surface of the poured concrete.